Bowmore Production

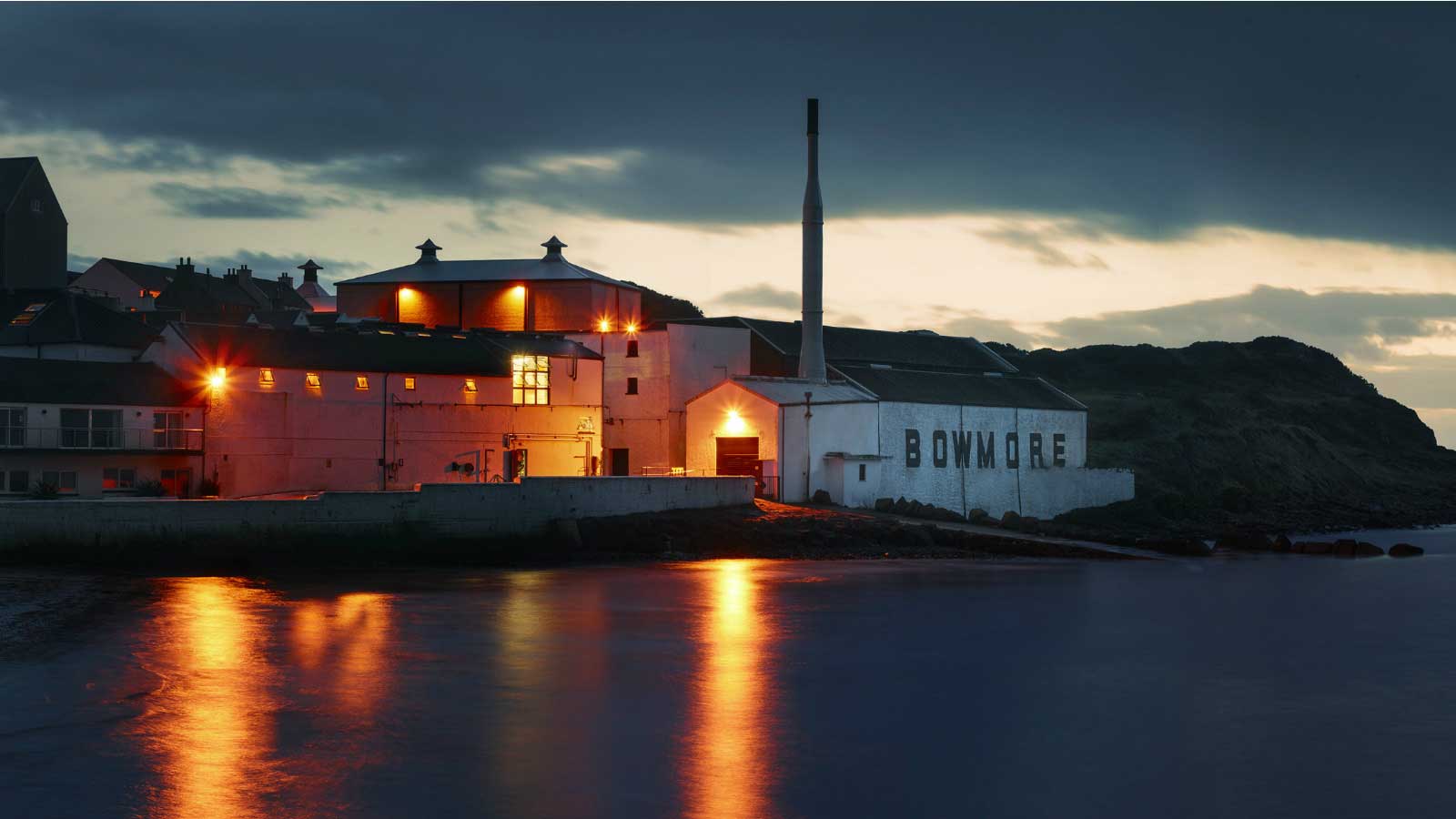

Amid Islay’s wild beauty, the fierce seas and Hebridean winds, Bowmore’s been making single malt Scotch whisky since 1779. Working with the finest quality oak casks, and a tradition that’s been passed down through generations, the master distillers use just three ingredients to make Bowmore single malt Scotch whisky: barley, yeast and water.

The soft fresh water from the nearby River Laggan, barley grown and malted on the island, painstakingly cultivated yeast, and the magnificent character of Islay all come together to create the Bowmore single malt Scotch whisky.

Malt Barns:

Unlike most distilleries, Bowmore still has its own Malt Barn, an airy shed where they malt their own barley and start the process of germination.

First, the raw barley is steeped for 27 hours in fresh water sourced from the nearby River Laggan. Then the soaked grains are spread out across the stone floors of the Malt Barn.

After 24 hours the barley is ready for turning, a vital step that keeps the grains aerated and cool, and the rate of germination slow and consistent. For the next six to seven days, the Maltmen will turn the damp barley every four hours, day and night, using large wooden shovels. Once it’s ready, the barley – now called “green malt” on account of the tiny shoots beginning to show – is taken to the kiln for drying.

The Kiln:

The kiln is where they halt germination and dry the barley so it can be milled into grist. It’s also where Bowmore single malt Scotch whisky is given its subtle peat smoke character.

Within the large kiln at Bowmore distillery are two furnaces that control the air temperature inside the kiln, up to 60C. The smoke from these furnaces billows up through the mesh floor – where the damp green malt is spread out – before meandering out from Bowmore’s iconic pagoda chimney.

For the first 18 hours of drying, peat is added to the furnaces. This gives the malted barley the subtle smoke flavour that is a key characteristic of Bowmore whisky. For the next 42 hours use hot air is used to gently dry the malt, keeping the temperatures low and slowly building up to 60°C. The hot air is recycled energy from the clever waste heat recovery system, the same system that heats the local swimming pool.

What is Peat?

Peat is an organic fuel that is commonly found in bogs across Islay and many of the other islands around Scotland. It’s made from compressed layers of organic material such as grass, heather and moss, and formed over thousands of years. Every year, during the warmer summer months, islanders will make the trip to the peats bogs to cut away slabs of peat, leaving them in piles to dry out, before taking home to use as a fuel for their fires. The smoke from a peat fire has a warm and distinctive aroma.

The Mill

Now dry, the malted barley is taken to our Porteus Malt Mill, where it is ground into grist. Our mill, a beautiful piece of engineering from a bygone age, was installed in the 1960s and has been running almost non-stop, ever since. The clean grain is ground through two sets of rollers, grinding 20kg at a time. The first set cracks open the grain whilst the bottom rollers, which are more tightly set, grind the grain down to grist. The grist then goes to the Mash House, where it’s added to hot water to produce a sugary liquid called wort.

The Mash House

Inside the Mash House is the Mash Tun, a huge pot of hot water heated by 80-year-old copper kettles.

In the Mash Tun, grist is added to the hot water where it mashes, or steeps, turning a rich dark colour and giving off a powerful malty aroma. This wort is then drained through the Mash Tun’s sieve-like bottom. We then mash the grain another two times, at slightly higher temperatures, so we can collect as much sugars from the barley as possible.

The leftover grain, known as draff, is sold to local farmers on Islay as winter cattle feed – just one of the many ways we minimise waste at the distillery.

The Tun Room:

Now cooled, it takes six hours to fill just one of the six massive Oregon Pine Washbacks with the sugary wort. Once full, it’s time to add yeast to the wort and let the miracle of fermentation begin.

In the full throes of fermentation, the wort will froth vigorously for about two days, giving off carbon dioxide as the ravenous yeast feeds on the sugars, converting them to alcohol. The liquid left over after fermentation is known as wash, and tastes and smells very similar to a strong malty beer with an ABV of about 8%.

The Still House

The Stillhouse is at the heart of Bowmore Distillery. Inside are the four stills where the spirit that will become whisky is made.

The first distillation takes place in our two Wash Stills. These great copper kettles are heated, and as the temperature approaches 93C the wash starts to bubble and the alcohol evaporate. The alcoholic vapour rises up and over the neck of the Wash Still and along the Lyne Arm to a condenser where it is turned into liquid again.

This liquid, now called Low Wine, will be about 22% ABV and needs to be distilled again in order to become spirit.

The Still House continued...

The second distillation is carried out in the smaller Spirit Still. As with the Wash Still, the Low Wine is heated and the spirit evaporates up the neck and along the Lyne Arm before condensing into raw spirit and travelling to the Spirit Safe.

It’s in the Spirit Safe that the Stillman draws off the the vapours in the three parts: Foreshots, Heart Of The Run and Feints. Clear like water but with an ABV of 69%, the Heart Of The Run is the only cut which fills our casks, ready to slowly mature in our No.1 Vaults.

Maturation

It’s at the maturation stage – arguably the most important part in our whisky journey – that the “new make spirit” develops its complex array of flavours and becomes Bowmore single malt Scotch whisky.

Because single malt Scotch whisky is too delicate to mature in new oak casks, we use a variety of used casks, carefully sourced from across the world, to develop the different colours and flavours of our whisky.

Maturation continued...

Legally, new make spirit only becomes whisky after it has been matured for three years. At Bowmore, we mature our whiskies for a minimum of nine years. During that time, our casks rest patiently, painstakingly stacked in our maturation warehouses, the most famous of which is the No.1 Vaults. It’s in here that each cask gradually absorbs the gentle Islay sea air, as if breathing in and out. This allows the spirit within to interact with the wood and absorb the unique characteristics of the cask, the atmosphere of the No.1 Vaults and of course the Islay itself.

History of Bowmore

Bowmore is Islay’s oldest distillery, and home to the world’s oldest whisky maturation warehouse, the No. 1 Vaults. It’s in this legendary warehouse that Bowmore whisky has been meticulously matured by the master distillers for nearly 240 years.

The first recorded mention of Bowmore Distillery dates from 1779 with Bowmore’s founder - David Simpson - buying the land in 1766.