Yamazaki Production

Yamazaki is distinguished by its uniqueness that a single distillery can produce a variety of whiskies, which a very few distillery in the world can match. It all started with Suntory’s pursuit of crafting world-class whisky to please the delicate Japanese palate.

Step 1

The mash is then distilled into colorless, transparent malts called new pot. The stills used for distillation are wash stills and spirit stills, each with eight variations in their shapes.

Step 2

At this point, heat is also added directly or indirectly, depending on which kinds of malts are to be made. This allows the consistency of the malts to vary greatly from strong and full-bodied to light and thin.

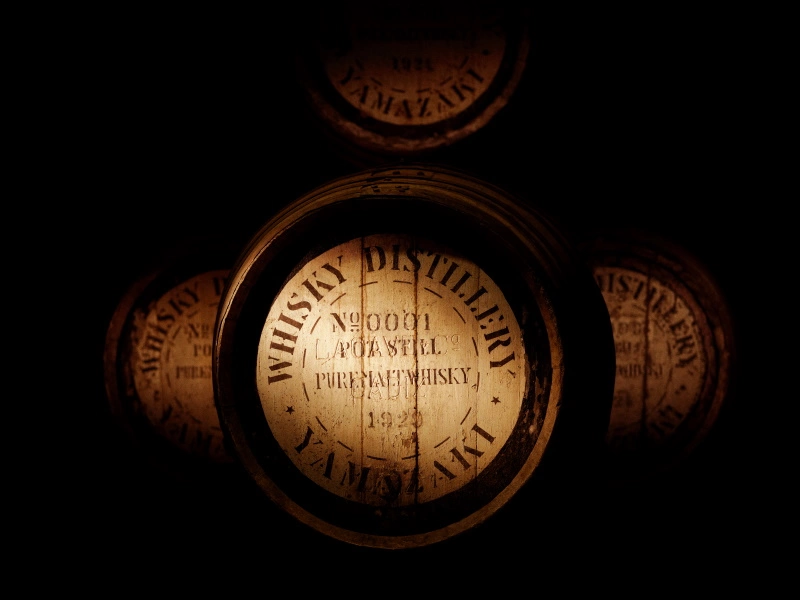

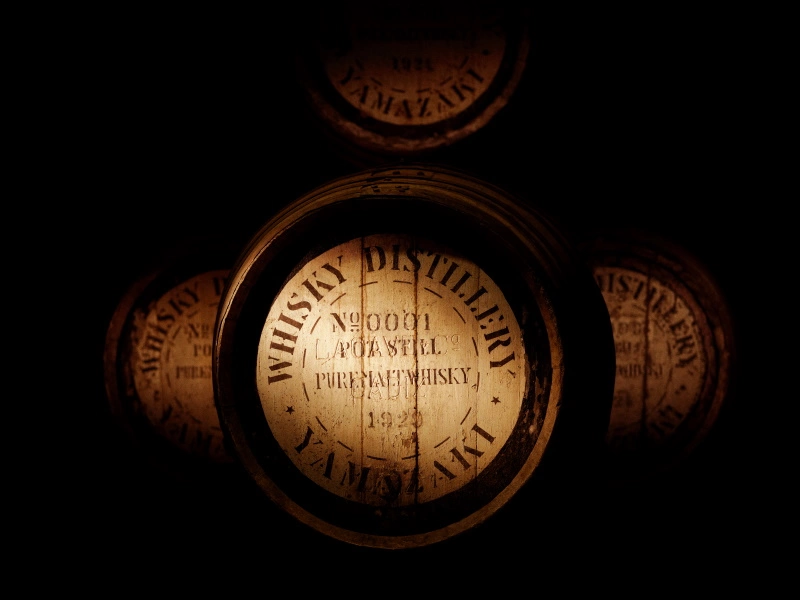

Step 3

The new pot will then be left to mature in wooden casks for years before it’s ready. Depending on the size and shape of the casks, a very diverse range of flavors can be developed over the years. And even when placed in the same types of casks, subtle differences in the whisky’s flavor and body can emerge depending on where the casks are stored, be it in the upper, middle, or lower shelf, or whether they are at the front or back.

Step 4

Entirely unique to the world, this meticulously controlled method of brewing whisky is what forms the rich and perfectly balanced flavors of Yamazaki® whisky.

Step 1

The mash is then distilled into colorless, transparent malts called new pot. The stills used for distillation are wash stills and spirit stills, each with eight variations in their shapes.

Step 2

At this point, heat is also added directly or indirectly, depending on which kinds of malts are to be made. This allows the consistency of the malts to vary greatly from strong and full-bodied to light and thin.

Step 3

The new pot will then be left to mature in wooden casks for years before it’s ready. Depending on the size and shape of the casks, a very diverse range of flavors can be developed over the years. And even when placed in the same types of casks, subtle differences in the whisky’s flavor and body can emerge depending on where the casks are stored, be it in the upper, middle, or lower shelf, or whether they are at the front or back.

Step 4

Entirely unique to the world, this meticulously controlled method of brewing whisky is what forms the rich and perfectly balanced flavors of Yamazaki® whisky.